info@chemdist.in

020-68143300

With goal to make “future fuel” consume less fuel in its production, CDMS’s team worked and with the knowledge and expertise gained over time in membrane technology, we redesigned traditional manufacturing process with our ingenious membrane based production technology, we call it as CDMS EthaMem G1.

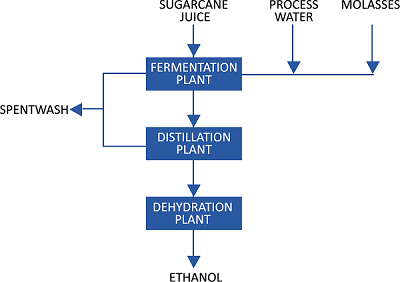

Whole ethanol production process has four major units.

1. Fermentation

2. Distillation

3. Dehydration

4. Spent wash Treatment

CDMS precisely identifies the short fall of each unit and systematically replaces conventional low performing technology with high performance.

Use of Ultra filtration Membrane for raw water treatment This will remove unwanted micro-organism present in feed water that might affect fermentation process.

Use of the Oxygen enrichment membranes in aerobic process which helps to increase the fermentation rate and to reduce the process time.

Use of high efficiency Chemdist made contact material (column internals/packings) for improving distillation performance.

Use of high life and high efficiency Pervaporation membranes for ethanol concentration/dehydration from 95% to 99.99%. This membrane dehydration unit gets rid of the high opex Azeotropic distillation or the high maintenance molecular sieve unit. The membrane life is in the range of 5-7 years.

Use of CDMS’s Membrane Distillation (MD) system replaces high opex multiple effect evaporator (MEE) and/or reverse osmosis system. Our MD unit is compact, highly energy efficient.

Turbulators is our patented heat exchanger insert used to enhance the heat transfer efficiency up to 30-40%.

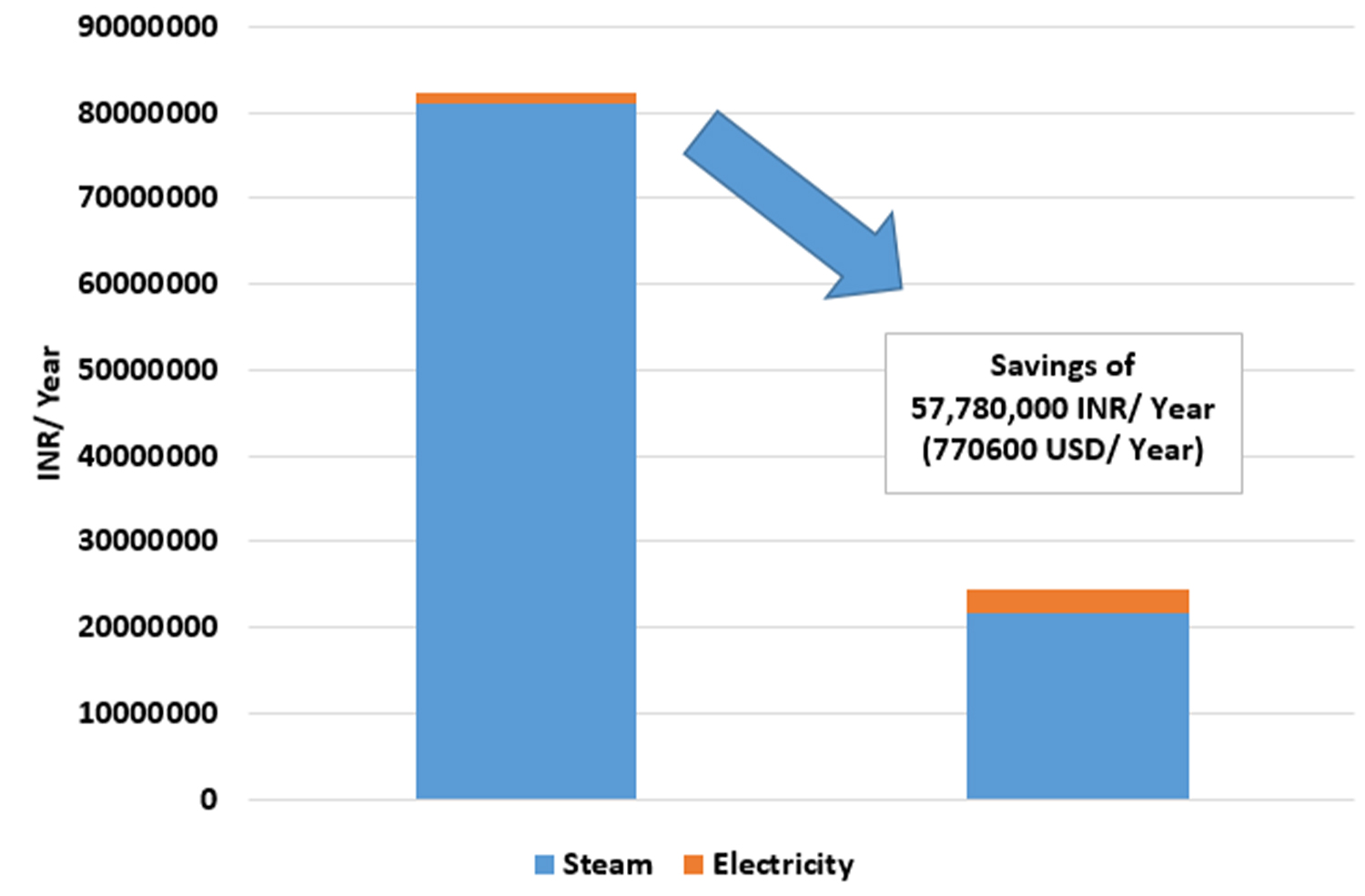

Conventional MEE vs CDMS HFMMD with HeatOn Pump

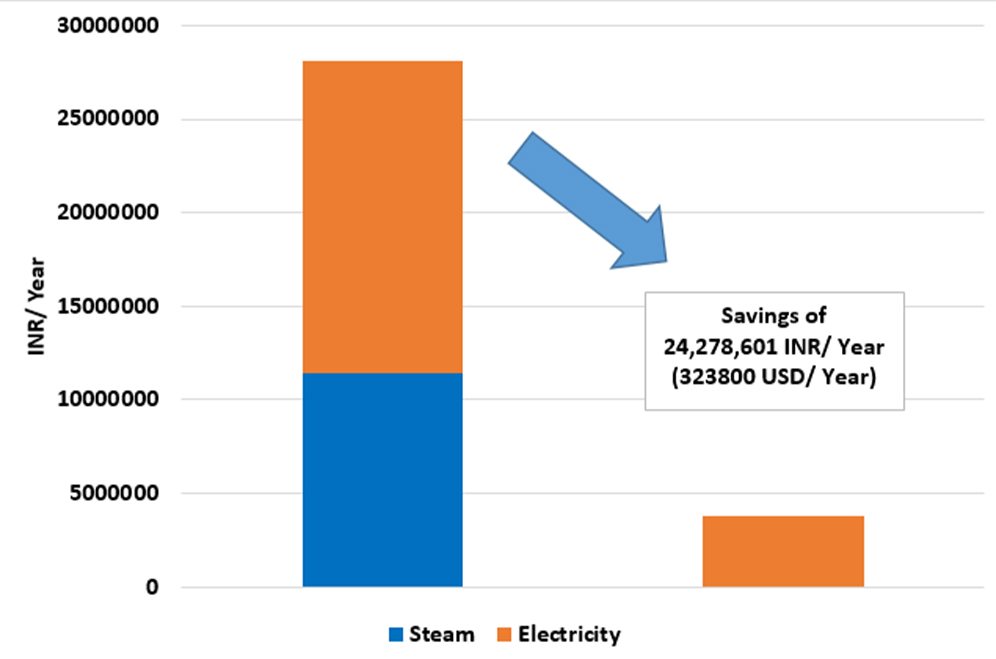

Total Savings

Conventional Azeotropic Distillation vs CDMS Pervaporation